Who we are

At DRIE-D we continue to set new standards to facilitate the handling of extreme loads in the most demanding circumstances, maintenance free and environmentally friendly.

Highly specialized in mechanical motion, our engineers strive to provide the best solution. Our experience and cooperative approach have learned to be the binding factor to create progressive designs.

Are you ready for a new and progressive approach, providing the best sustainable and reliable solution for your mechanical motion challenge?

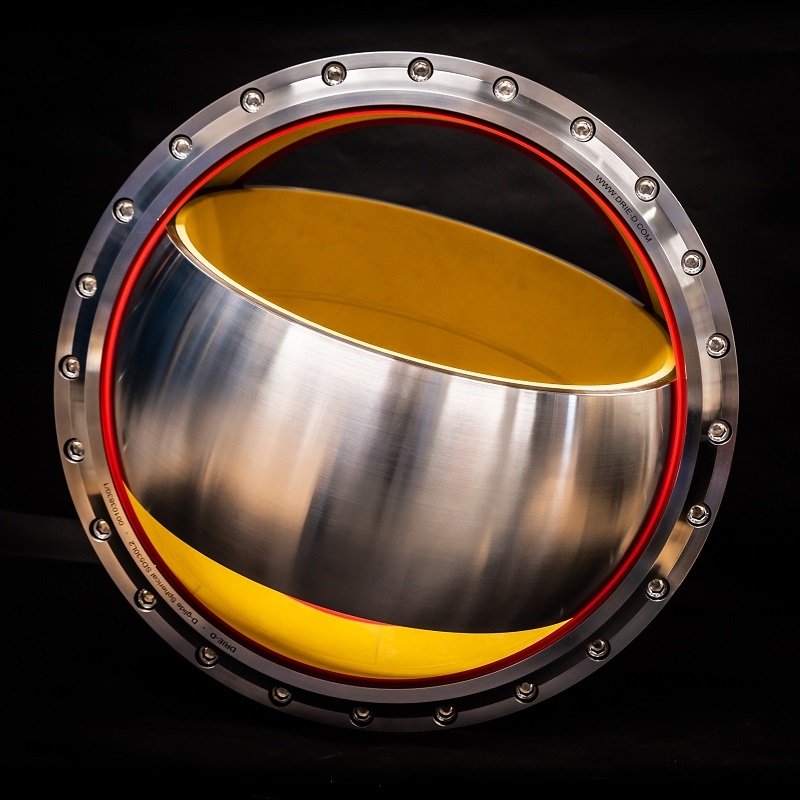

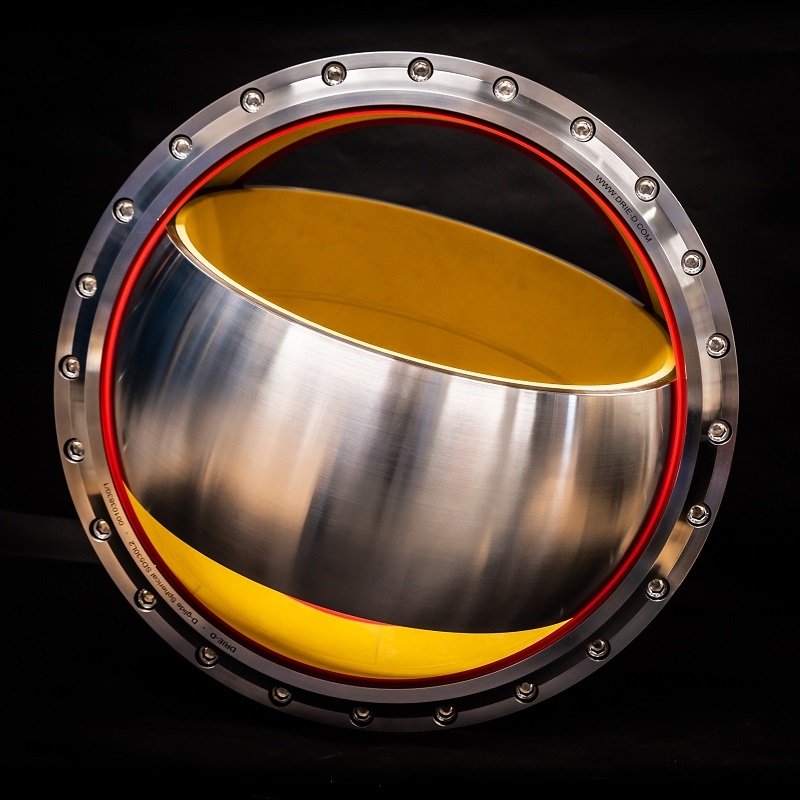

Bearing Technology

Friction Solutions

Our history

Our company was founded in the 90's

In cooperation with an innovative manufacturer of composite bearing material, we started to explore the use of composite in many ways. Together with two leading manufacturers of friction materials, DRIE-D started with the supply of robust, reliable products for different applications.

Our mission

To create new limits in engineering and design of composite bearings and friction solutions, sustainable, maintenance free and preserving the earth for the next generation. DRIE-D gathered a team of dedicated engineers, pure specialists thriving on the challenges of the modern engineering world.

Decades of experience

Over the years we have been involved in progressive project in diverse markets, challenging our creativity and innovative approach in design and engineering. In these projects we learned that our knowledge and experience was the binding factor pushing the limits by the use of progressive composite bearing design. When technical feasibility is challenging, we are determined to find a solution that will set a new standard for the whole industry.

DRIE-D: Present and the future

Setting new standards in solutions for everything that needs to rotate or slide (or a combination of both). With the use of our patented D-glide®, composite bearings allow higher loads than virtually all other plain bearings and have less friction and less wear.

As a competent player in friction materials, we provide reliable and robust friction solutions for different applications. With our knowledge of friction materials and our experience in challenging projects, we create progressive, sustainable and reliable friction solutions.

Combined, our knowledge of D-glide®, composite bearings, friction materials and our experience in challenging projects all come together in container handling and port equipment, resulting in improved components for mechanical motion.

Why customers contact us?

Bearing Technology

To create the best possible bearing designs, DRIE-D has a team of dedicated engineers, pure specialists thriving on the challenges of the modern engineering world.

Friction Solutions

Supplying brake linings, friction discs, clutch facings and other components made with friction material. Engineering, solving problems and deliver to end users.

D-glide® composite

Our specially developed durable D-glide® composite bearing material allows for technical opportunities that exceed those of all traditional bearings.

Our services

Design & Engineering

Our engineers support you from the conceptual phase to detailed engineering in making the right choices and incorporate additional advantages.

Project Management

Challenging and complex projects require good management. A multidisciplined team is put together for your project and aligned to accommodate your requirements.

Finite Elements Analysis

Our engineers will validate any design both mathematically as well as by using FEA software. Our profound knowledge of our bearing materials enables us to make detailed FEM analyses.

On-site support

Our trained service engineers are specialized in bonding processes on site and can be deployed also for mounting support. Also we have specialists available for inspections of existing equipment.

Bonding

Specialized in certified friction materials and D-glide® bearing material, we have acquired profound knowledge of bonding. Our own developed bonding procedures ensure verifiable quality and reliability.

Transport services

Care for our products also includes fast, reliable and careful delivery. Our own transport department supplies our products from stock to your site and gives support on international shipping.

Our projects

Heave Chief

A pivotal challenge DRIE-D faced in the Seaqualize Heave Chief project was ensuring minimal friction during continuous motion under high loads.

Spud guides

Spud guides with D-glide® offer long life thanks to the excellent wear resistance of D-glide® and smooth operation due to the low friction values.

Hardt Hyperloop

We are proud that European Hyperloop Center, an arena of cutting-edge transportation research, is fully equipped with custom designed D-glide® components.

AIN Dubai

Mega bearings for largest observation wheel. An innovative design of mega bearings from D-glide® bearing tiles instead of roller bearings.